U-shape Paper Straw Production Line

A U-shape paper straw production line is a specific configuration of a paper straw production line that is designed in the shape of the letter "U." It typically consists of various machines and processes arranged in a U-shaped layout to optimize workflow and increase production efficiency.......

Send Inquiry

Product Description

A U-shape paper straw production line is a specific configuration of a paper straw production line that is designed in the shape of the letter "U." It typically consists of various machines and processes arranged in a U-shaped layout to optimize workflow and increase production efficiency. The U-shape design allows for a continuous flow of materials and reduces the need for manual handling.

Here are the key components and processes typically found in a U-shape paper straw production line:

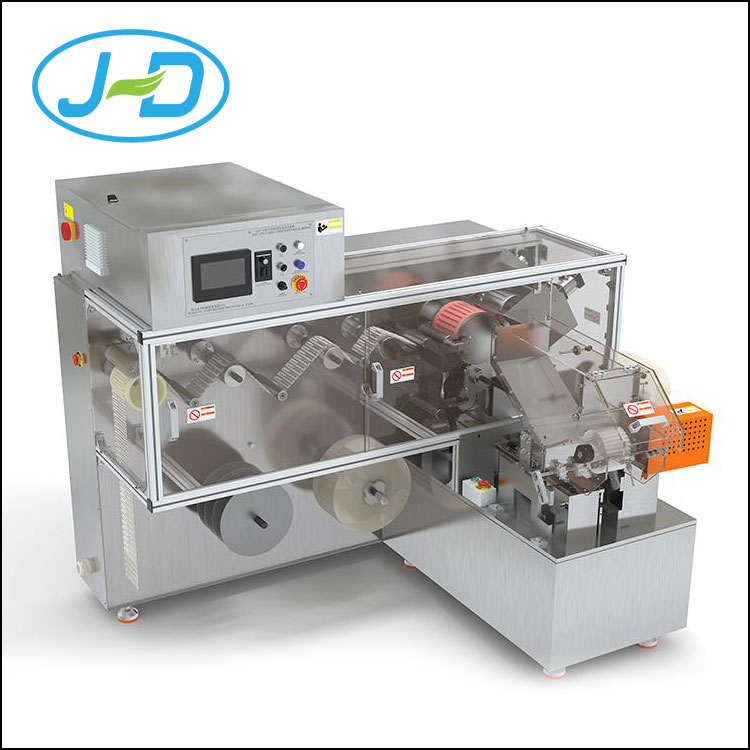

1. Paper Straw Unwinding Machine: This machine unwinds the paper roll and feeds it into the production line. It ensures a continuous supply of paper to the subsequent machines.

2. Paper Printing Machine (Optional): If custom printing or branding is required on the paper straws, a printing machine may be included in the production line. It can print patterns, logos, or other desired artwork onto the surface of the paper.

3. Straw Forming and Cutting Machine: This machine is responsible for shaping the paper into a tube-like structure and cutting it into individual straw lengths. It may consist of multiple stations to increase production capacity.

4. Gluing and Sealing Machine: After the straws are cut, a gluing machine applies adhesive to seal the edges and ensure the straws remain liquid-tight. It ensures proper bonding and secure sealing of the straws.

5. Quality Control and Inspection: Throughout the production line, quality control measures and inspections are carried out to ensure the paper straws meet the required standards. This includes checking for defects, dimensions, glue strength, and overall quality of the finished straws.

6. Straw Collecting and Packaging Machine: Once the straws are produced, a collecting machine gathers and arranges the straws in the desired order for packaging. A packaging machine then bundles and packages the straws, ready for distribution and sale.

The U-shape layout allows for a smooth and efficient flow of materials from one machine to the next, minimizing the need for manual handling and reducing production time. It optimizes space utilization and can accommodate higher production capacities compared to linear or circular production line configurations.

When setting up a U-shape paper straw production line, it's important to consider factors such as the speed of production, quality control measures, material sourcing, and workflow optimization. Additionally, compliance with relevant regulations and standards for food-grade paper and adhesives should be ensured.