What material is used for flexible LED strips?

2024-06-11

Flexible LED strips are composed of various materials that provide both the necessary flexibility and the electronic functionality required for their operation. Here are the primary materials used in flexible LED strips:

1. Substrate Material

- Flexible Printed Circuit Board (FPCB): The primary material for the substrate of flexible LED strips is often a flexible printed circuit board made from polyimide (PI) or polyethylene terephthalate (PET). These materials provide flexibility, durability, and thermal stability, allowing the strip to bend and conform to different shapes and surfaces.

2. LEDs (Light Emitting Diodes)

- Semiconductor Material: The LEDs themselves are made from semiconductor materials such as gallium arsenide (GaAs), gallium phosphide (GaP), or gallium nitride (GaN), which emit light when an electric current passes through them.

- Encapsulation: LEDs are typically encapsulated in an epoxy resin or silicone to protect them from environmental factors and to help disperse heat.

3. Conductive Traces

- Copper: Conductive traces on the FPCB are typically made of copper. The copper traces provide the electrical pathways necessary to connect the LEDs and other components, allowing current to flow through the strip.

4. Solder Mask

- Epoxy or Polyimide: A solder mask is applied to protect the conductive traces and prevent short circuits. This layer is often made from epoxy or polyimide and can be colored (commonly white or black).

5. Adhesive Layer

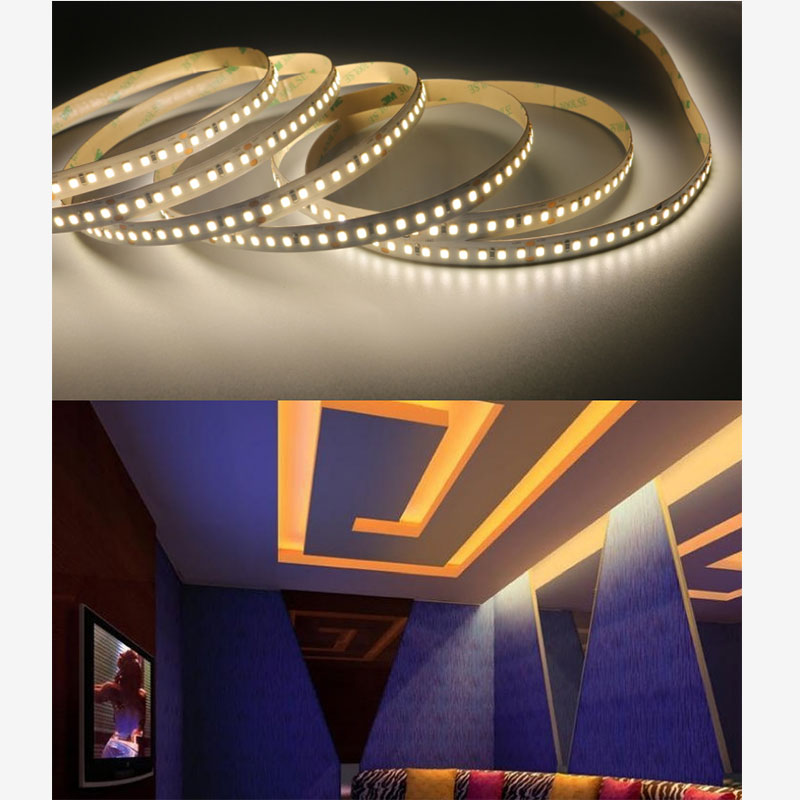

- Double-Sided Tape: The back of the flexible LED strip often features a layer of double-sided adhesive tape, such as 3M adhesive. This allows the strip to be easily mounted on various surfaces.

6. Protective Coating

- Silicone or Epoxy: To protect the LEDs and circuitry from moisture, dust, and mechanical damage, a flexible LED strip may be coated with a layer of silicone or epoxy. This coating enhances the durability and longevity of the strip, especially for outdoor or damp environments.

7. Resistors and Other Components

- Surface-Mount Device (SMD) Resistors: To control the current flowing through the LEDs, surface-mount resistors are often included on the flexible PCB. These resistors are made from materials like metal oxide or carbon film.

- Additional Components: Depending on the design, additional components such as capacitors, diodes, and integrated circuits (ICs) might be included to manage power, control the lighting effects, and provide connectivity options.

Summary

Flexible LED strips are composed of several materials that combine to create a functional, flexible lighting solution. The key materials include:

- Flexible Printed Circuit Board (FPCB): Typically made from polyimide (PI) or polyethylene terephthalate (PET).

- LEDs: Made from semiconductor materials like gallium arsenide (GaAs), gallium phosphide (GaP), or gallium nitride (GaN).

- Conductive Traces: Made of copper.

- Solder Mask: Made from epoxy or polyimide.

- Adhesive Layer: Often double-sided tape like 3M adhesive.

- Protective Coating: Silicone or epoxy.

- Additional Components: Including resistors, capacitors, diodes, and ICs.

These materials collectively ensure the flexibility, durability, and functionality of the LED strips, making them suitable for a wide range of applications from decorative lighting to functional illumination in various environments.