Overview of how YAG laser welding machines work

2023-10-16

A YAG (Yttrium Aluminum Garnet) laser welding machine is a type of laser welding equipment that uses a YAG crystal as the active medium to produce laser beams for welding purposes. YAG laser welding machines are commonly used in industrial applications to perform high-precision welding on various types of materials, including metals, alloys, and some non-metallic materials.

Here's an overview of how YAG laser welding machines work and their applications:

1. Principle of Operation: YAG laser welding machines operate based on the principle of laser-induced heat generation. When an electrical pulse is applied to the YAG crystal, it emits a laser beam with a specific wavelength, typically in the near-infrared range. This laser beam is focused on the welding area using lenses, mirrors, and other optical components.

2. Welding Process: The intense laser beam generates heat at the point of focus, causing the material to melt and form a weld pool. As the material cools and solidifies, a strong welded joint is formed. The focused laser beam allows for precise control of heat input, resulting in minimal distortion and high-quality welds.

3. Pulsed and Continuous Wave (CW) Modes: YAG laser welding machines can operate in either pulsed or continuous wave (CW) modes. In the pulsed mode, the laser beam is emitted in short bursts, while in the CW mode, the laser beam is emitted continuously. Pulsed mode is often preferred for welding applications as it allows for better control of heat input and reduces the risk of overheating.

4. Wavelength: YAG lasers typically emit laser beams with wavelengths around 1064 nanometers (nm). This wavelength is suitable for welding many metals, including stainless steel, titanium, aluminum, and other alloys.

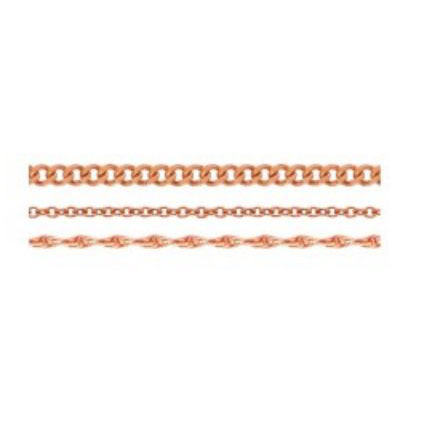

5. Applications: YAG laser welding machines are used in various industries, including automotive, aerospace, electronics, medical devices, jewelry, and precision engineering. They are particularly useful for applications that require high precision, small heat-affected zones, and minimal distortion, such as delicate electronic components, medical implants, and fine jewelry.

6. Advantages: YAG laser welding offers several advantages, including excellent welding quality, precise control of heat input, the ability to weld dissimilar materials, minimal distortion, and reduced post-welding processing.

7. Limitations: YAG lasers are less efficient and have lower power output compared to other laser types like fiber lasers and CO2 lasers. This can affect their speed and suitability for certain high-power or high-throughput applications.

8. Maintenance: YAG laser welding machines require regular maintenance to ensure the performance and longevity of the laser components. This includes cleaning optical elements and replacing flash lamps (used to pump the YAG crystal) as they degrade over time.

Overall, YAG laser welding machines are valuable tools for precision welding applications, providing a combination of high-quality welds and minimal thermal distortion. However, the choice between YAG lasers and other laser types depends on factors such as material type, required power levels, and specific application requirements.