What is the purpose of a vertical slurry pump?

2023-10-16

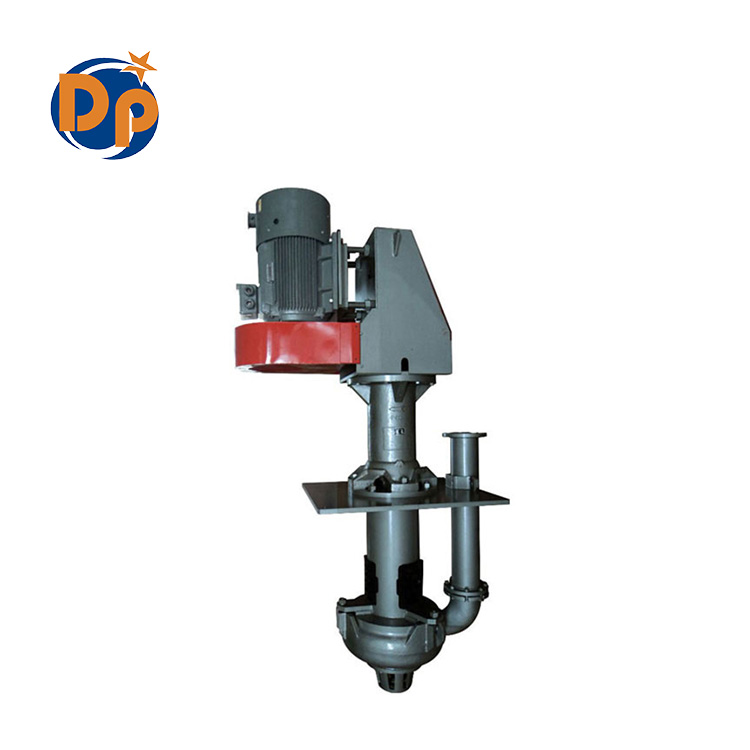

A vertical slurry pump is a type of centrifugal pump specifically designed for handling abrasive and high-density slurries in vertical applications. Unlike horizontal slurry pumps, which have a horizontal shaft, the vertical slurry pump has a vertical shaft and is typically immersed directly into the slurry or sump.

The purpose of a vertical slurry pump is to efficiently transport and transfer slurries from one location to another in vertical or semi-vertical applications. Here are some key purposes and advantages of using a vertical slurry pump:

1. Submerged Operation: Vertical slurry pumps are often used in applications where the pump is submerged in the slurry or sump. This eliminates the need for priming and improves the pump's efficiency by eliminating airlock issues.

2. Space-Saving Design: The vertical configuration of these pumps makes them ideal for installations where space is limited. They have a smaller footprint compared to horizontal pumps and can be installed in confined spaces or where floor space is restricted.

3. Pumping Efficiency: Vertical slurry pumps are designed to operate with high efficiency, ensuring effective transportation of abrasive slurries with minimal energy consumption. They are capable of handling high head pressures and can pump the slurry vertically over significant distances.

4. Solids Handling: These pumps are specifically engineered to handle slurries containing a high concentration of solid particles. The impeller design and pump casing are optimized to pass large-sized solids without clogging or excessive wear, ensuring reliable and continuous operation.

5. Versatile Applications: Vertical slurry pumps find application in various industries, including mining, mineral processing, dredging, coal preparation, chemical processing, and wastewater treatment. They are commonly used in processes such as mine dewatering, ash handling, tailings transport, and sump drainage.

6. Customizable Options: Vertical slurry pumps can be customized to suit specific application requirements. They can be designed with different impeller types, materials of construction, and various sealing options to handle different slurry characteristics and operating conditions.

Vertical slurry pumps are typically driven by electric motors and are available in different configurations, such as cantilever, sump, and submerged designs. They are a reliable and efficient solution for transporting abrasive slurries vertically, offering advantages in terms of space-saving, ease of installation, and efficient slurry handling in a range of industrial applications.